Industry news

Tractor Parts: Rubber and Plastic

Tractors help put food on our tables and bring innovations to industry. Wheat, corn, soybeans, and potatoes feed hungry humans. Oats, alfalfa, and other grains are also eaten by livestock. Today, crops such as corn are used in everything from ethanol to processed foods to bioplastics and fillers for rubber. Polymers and elastomers also have a great many uses, including the rubber and plastic parts used on tractors and other mobile specialty vehicles.

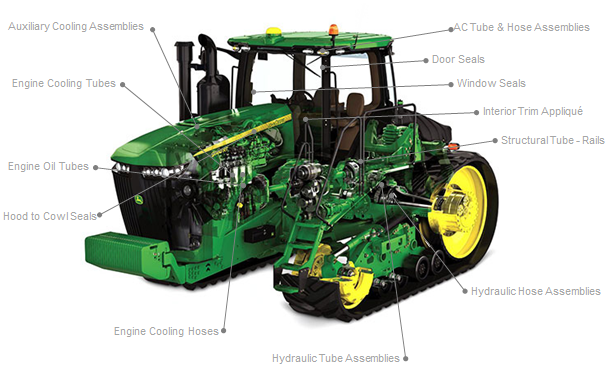

Recently, a supplier shared with us the image that accompanies this blog entry. As you can see, there are callouts for plenty of parts. For years, AGEP has supplied door seals, window rubber, and interior trim for roll-over protection structures (ROPS). Our custom fabrication specialists have also supplied rubber floor mats and thermal and acoustic insulation for engine bays and tractor cabs. Let’s take a look at some other rubber and plastic tractor parts AGEP can provide.

Under the Hood

Most farm tractors that are built in North America have liquid-cooled engines. Typically fueled by diesel or gasoline, these power plants use an engine-driven pump to circulate coolant through passages in the engine block and cylinder heads. Engine cooling tubes and engine cooling hoses are important parts of this system, and are made of rubber and plastic materials that resist water, antifreeze, and corrosion inhibitors. These coolant tubes and hoses must also resist extreme service temperatures.

Coolant hoses for tractor engines are often made of elastomers such as silicone, EPDM, or neoprene. Runs of hose are either straight or branched, and may be reinforced with wire or fabric. For radiator hose, the SAE 20R4 D1 standard describes construction characteristics. Rubber and plastic parts for engine cooling systems may also include auxiliary cooling assemblies for tractor transmissions. High temperatures can cause transmission fluid to break down and increased component wear to occur.

In addition to under-the-hood cooling systems, rubber parts are also used to support engine lubrication. With smaller tractor engines, oil tubes are often made of cost-effective, oil-resistant rubber such as neoprene or nitrile. On engines of all sizes, the oil cap may be made of a thermoplastic such as polyvinyl chloride (PVC). Tractors also use hood to cowl seals made of weather-resistant rubber such as EPDM. These gaskets are fabricated from weather stripping and provide a reliable seal.

In the Cab and Around the Tractor

Tractor cabs or cabins also provide protection from weather-related conditions. Operators, instruments, and interior components such as seats, armrests, and steering wheels can avoid rain, wind, and strong sunlight. Modern tractor interiors support operator comfort, and often feature satellite radio, heat, and air conditioning. AC tube and hose assemblies are made of polymers that resist specific refrigerants. Butyl rubber is a common choice for the hose inner tube, and may be reinforced with braided steel wire.

Air conditioning hose needs to meet application requirements for maximum working pressure (psi) and working temperature range. Compliance with the SAE J2064 Type B, Class I standard indicates a hose’s suitability for off-road use. Farm tractors and agricultural equipment such as combines also need hydraulic hose assemblies, hydraulic tube assemblies, and structural tube rails. These rubber and plastic parts must resist hydraulic fluid, and meet various general, dimensional, and performance specifications.

For the operator, the tractor cabin contains the controls for several hydraulic systems. In addition to steering and braking, hydraulics are used to raise and lower loaders, mowers, cutters, and seeders. Each implement may use rubber or plastic parts. With the flip of a switch, the tractor’s operator can also activate windshield wipers with rubber blades. Rubber door and window seals, edge trim, and floor mats all provide examples of how elastomers are used in agricultural machinery.

How Can We Help You?

AGEP doesn’t build tractors, but we do specialize in the custom-fabrication of rubber and plastic parts that help keep them running smoothly. Our experienced solutions providers are ready to help you select the right compounds, design seals and insulation with all of your requirements in mind, and strengthen your supply chain. How can we help you?

Categories

News

Contact Us

Contact: Agriculture Equipment Parts

Phone: 86(0)15869109368

Tel: 86-571-89967020

E-mail: qjwjgc@gmail.com

Add: Hangzhou City Zhejiang Province China