Industry news

Compatible equipment models: 2151636:

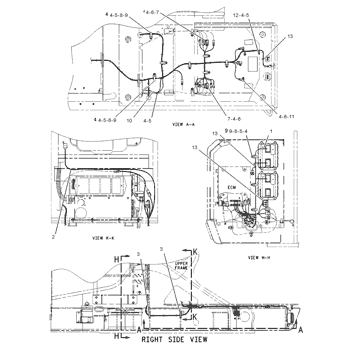

Illustration 7 g00286046

Graph For Total Eccentricity (1) Total vertical eccentricity. (2) Total horizontal eccentricity. (3) Acceptable value. (4) Unacceptable value.

On the graph for total eccentricity, find the point of intersection of the lines for vertical eccentricity and horizontal eccentricity.

If the point of intersection is in the range marked "Acceptable", the bore is in alignment. If the point of intersection is in the range marked "Not acceptable", the flywheel housing must be changed.Face Runout (axial eccentricity) of the Flywheel

Illustration 8 g00286049

Checking Face Runout Of The Flywheel

Refer to Illustration 8 and install the dial indicator. Always put a force on the crankshaft in the same direction before the dial indicator is read. This will remove any crankshaft end clearance.

Set the dial indicator to read 0.0 mm (.00 inch).

Turn the flywheel at intervals of 90 degrees and read the dial indicator.

Take the measurements at all four points. Find the difference between the lower measurements and the higher measurements. This value must not exceed the maximum permissible face runout (axial eccentricity) of the flywheel.Bore Runout (radial eccentricity) of the Flywheel

Illustration 9 g00286054

Checking Bore Runout Of The Flywheel (1) 7H-1945 Holding Rod. (2) 7H-1645 Holding Rod. (3) 7H-1942 Dial Indicator. (4) 7H-1940 Universal Attachment .

Install the 7H-1942 Dial Indicator (3). Make an adjustment of the 7H-1940 Universal Attachment (4) so that the dial indicator makes contact on the flywheel.

Set the dial indicator to read 0.0 mm (.00 inch).

Turn the flywheel at intervals of 90 degrees and read the dial indicator.

Take the measurements at all four points. Find the difference between the lower measurements and the higher measurements. This value must not exceed the maximum permissible bore runout (radial eccentricity) of the flywheel.

Illustration 10 g00286058

Flywheel Clutch Pilot Bearing Bore

Take the measurements at all four points. Find the difference between the lower measurements and the higher measurements. This value must not exceed the maximum permissible pilot bore runout of the flywheel.Vibration Damper

Damage to the vibration damper or failure of the vibration damper will increase vibrations. This will result in damage to the crankshaft.Replace the vibration damper if the vibration damper is bent or if the vibration damper is damaged. Replace the vibration damper if the bolt holes are oversize. Replacement of the vibration damper is also needed at the time of a crankshaft failure due to torsional forces.Rubber Vibration Damper (If Equipped)

Illustration 11 g00295949

Rubber vibration damper (1) Crankshaft. (2) Hub. (3) Rubber. (4) Ring. (5) Alignment marks. If the rubber vibration damper is damaged or the bolt holes in the rubber vibration damper fit loosely, replace the rubber vibration damper. Replace this component if the rubber vibration damper fails due to torsional forces.The rubber vibration damper displays alignment marks on the hub and on the ring. These marks indicate the condition of the rubber vibration damper.If the alignment marks are not aligned, the rubber portion of the rubber vibration damper has separated from the hub and/or from the ring. When the alignment marks are not aligned, replace the rubber vibration damper.A used rubber vibration

Categories

News

Contact Us

Contact: Agriculture Machinery Parts

Phone: 86(0)15869109368

Tel: 86-571-89967020

E-mail: dawopu@gmail.com

Add: Hangzhou City Zhejiang Province China